वर्तमान में टाइटेनियम क्लब पोल प्रौद्योगिकी में रहने वाली चीजें पेश की जा रही हैं – TA1, TA2, Tc4, Ta18, gr4, gr2, gr5, और gr7। ये विशिष्ट चीजें पूरी तरह से उपलब्ध होंगी जिनका अंतिम वास्तविकता उच्च स्तर की सराहना प्राप्त है। सराहना एक शीर्षक है जो वास्तव में टाइटेनियम क्लब पोल्स की दुनिया में बहुत प्रसिद्ध है। इसकी चीजें अपनी अधिकतम ऊर्जा और स्वतंत्रता के लिए प्रसिद्ध हैं। ग्राहक इन टाइटेनियम पोल्स और छड़ों को विभिन्न उपयोगों के लिए विभिन्न कंपनियों, जिनमें विमान उद्योग, सशस्त्र बल, चिकित्सा और अभियांत्रिकी शामिल हैं, पर विश्वास करते हैं। टाइटेनियम पोल TA1 शुद्ध टाइटेनियम से बना है और सराहना इसकी शुद्धता का वादा करती है। इसमें अद्भुत संदीधन, उच्च ऊर्जा और उत्कृष्ट डक्टिलिटी होती है, जिससे यह विभिन्न व्यापारिक उपयोगों के लिए आदर्श विकल्प है। TA2 टाइटेनियम क्लब पोल सराहना द्वारा बहुत प्रसिद्ध है और इसमें अद्भुत स्वतंत्रता, रासायनिक विशिष्टता और थर्मल गुण होते हैं, जिससे यह विभिन्न विद्युत, समुद्रीय और रासायनिक कंपनियों में उपयोग के लिए उपयुक्त है। Tc4 टाइटेनियम क्लब पोल तापमान प्रतिरोध, ऊर्जा और विश्वसनीयता के तीव्र गुणों वाला मिश्रण है, जिससे यह विमान और सुरक्षा कंपनियों में आमतौर पर प्रयोग किया जाता है। Ta18 टाइटेनियम क्लब पोल एक शीर्ष ग्रेड का मिश्रण है जो विमान अनुप्रयोगों जैसे उच्च-तापमान परिवेशों में उपयोग के लिए आदर्श है। इसमें अद्भुत संदीधन, उच्च तापमान प्रतिरोध और दुर्बलता प्रतिरोध होता है। gr4 टाइटेनियम क्लब पोल एक लाइटवेट और संदीधन-प्रतिरोधी टाइटेनियम है। यह आमतौर पर विमान और चिकित्सा उपकरणों में पाया जाता है। gr2 टाइटेनियम क्लब पोल बहुत लचीला है और इसे अभियांत्रिकी, तेल और गैस, और समुद्रीय कंपनियों जैसी विभिन्न कंपनियों में विश्वास किया जाता है। gr5 टाइटेनियम क्लब पोल की तुलना में अधिक शक्ति और दृढ़ता होती है, जिससे यह विभिन्न कंपनियों, जिनमें ऑटोमोबाइल और विमान उद्योग शामिल हैं, के लिए व्यापक उपयोगों के लिए सबसे अच्छा है। अंत में, फिर भी सबसे कम, gr7 टाइटेनियम क्लब पोल एक बहुत ही दृढ़ और संदीधन-प्रतिरोधी टाइटेनियम है जिसमें अद्भुत वेल्डिंग क्षमता और रूपांतरण क्षमता होती है। यह रासायनिक प्रसंस्करण और अन्य संदीधन परिवेशों में आमतौर पर उपयोग किया जाता है। सराहना के टाइटेनियम क्लब पोल उत्पादों के साथ, ग्राहकों को अपनी आवश्यकताओं को पूरा करने और उनकी उम्मीदों से बेहतर परिणाम प्राप्त करने की गारंटी है। अपना ऑर्डर दें और एक ही पैकेज में विविधता, गुणवत्ता और कुशलता का आनंद लें।

चैनल। A एक अनुभवी मेटल ट्यूब आपूर्तिकर्ता है, टाइटेनियम ट्यूब, एल्यूमिनियम ट्यूब, स्टेनलेस स्टील ट्यूब में विशेषज्ञ है, और कारखाने के लिए पूर्ण उत्पादन लाइन भी प्रदान कर सकता है। ओ ग्र1 ग्र2 ग्र9 टाइटेनियम सीमिंग ट्यूब के उत्पादन में प्रतिबद्ध है, विशेष रूप से ग्र9 टाइटेनियम सीमिंग ट्यूब के उत्पादन में कीमत और डिलीवरी समय के लिए फायदे है। ओ 6000 श्रृंखला और 7000 श्रृंखला एल्यूमिनियम ट्यूब के उत्पादन में प्रतिबद्ध है, विशेष रूप से 7001, 7005, 7075 एल्यूमिनियम टेंट पोल पाइप और तीर ट्यूब के उत्पादन में कई फायदे है। ओ ne स्टेनलेस स्टील बिना जोड़े और वेल्डेड पाइप के उत्पादन में प्रतिबद्ध है, विशेष रूप से विभिन्न प्रकार के चिकित्सा स्टेनलेस स्टील कैपिलरी पाइप के उत्पादन में।

टाइटेनियम ट्यूब / टाइटेनियम पाइप। टाइटेनियम ट्यूब हल्का वजन का होता है, बल में अधिक और यांत्रिक गुणों में शीर्ष स्तर का। इसका उपयोग ऊष्मा विनिमय उपकरणों में बहुत किया जाता है, जैसे कि ट्यूब और ट्यूब ऊष्मा विनिमयक, कोइल ऊष्मा विनिमयक, सर्पिल ट्यूब ऊष्मा विनिमयक, संघनी, वाष्पीकरणक और परिवहन पाइपलाइन। कई परमाणु ऊर्जा उद्योग अपने इकाइयों के लिए टाइटेनियम ट्यूब का उपयोग मानक ट्यूब के रूप में करते हैं

टाइटेनियम ट्यूब / टाइटेनियम पाइप। टाइटेनियम का घनत्व 4.506-4.516g/सेमी^3 है, पिघलने का बिंदु 1668 है, और उबालने का बिंदु 3535 है। इसलिए टाइटेनियम में कम वजन, उत्कृष्ट बल, और अच्छी चुंबकीय विशेषताएँ होती हैं, कम घनत्व, उत्कृष्ट संक्षारण प्रतिरोध विशेषताएँ, उच्च विशिष्ट बल और उच्च तापमान प्रतिरोध विशेषताएँ होती हैं, इसलिए इसका उपयोग रसायन उद्योग, चिकित्सा क्षेत्र, इलेक्ट्रॉनिक्स निर्माण, यांत्रिक भाग, ऑटोमोबाइल उद्योग, और विमान उद्योग में बहुत किया जाता है

टाइटेनियम – विमान उद्योग के अनुप्रयोग

टाइटेनियम – औद्योगिक अनुप्रयोग

टाइटेनियम – उपभोक्ता और आर्किटेक्चरिक अनुप्रयोग

टाइटेनियम – मेडिकल अनुप्रयोग

नाम |

टाइटेनियम ट्यूब और पाइप |

|

मानक

|

ASTM B338/ASME SB338, ASTM B337/ASME SB337, ASTM B861/ASME SB861, ASTM B862/ASME SB862, AMS4911, AMS4928 |

|

सामग्री ग्रेड |

Gr1, Gr2, Gr4, Gr7, Gr9, Gr11, Gr12, आदि |

|

लंबाई

|

≤14000mm |

|

आकार मिम

|

व्यास 3-508mm |

|

अनुभाग आकार

|

गोलाकार \ वर्गाकार |

|

सहिष्णुता

|

a) बाहरी व्यास: +\/– 0.01 मिमी |

|

|

b) मोटाई: +\/– 0.01 मिमी |

|

c) लंबाई: +\/– 0.1 मिमी |

सतह |

पिकलिंग, एनीलिंग, पोलिशिंग, ब्राइट |

|

विशेषता

|

1. कम घनत्व और उच्च ताकत

2. अद्भुत ग्रेसियन प्रतिरोध

3. गर्मी के प्रभाव का अच्छा प्रतिरोध

4. अद्भुत क्रायोजेनिक गुणों की धारण क्षमता

5. अमैग्नेटिक और नॉन-टॉक्सिक

6. अच्छी थर्मल गुण

7. कम ईलास्टिसिटी मॉड्यूलस |

|

परीक्षण |

स्क्वैश परीक्षण, विस्तारित परीक्षण, पानी का दबाव परीक्षण, क्रिस्टल रोट परीक्षण, गर्मी का उपचार, NDT |

|

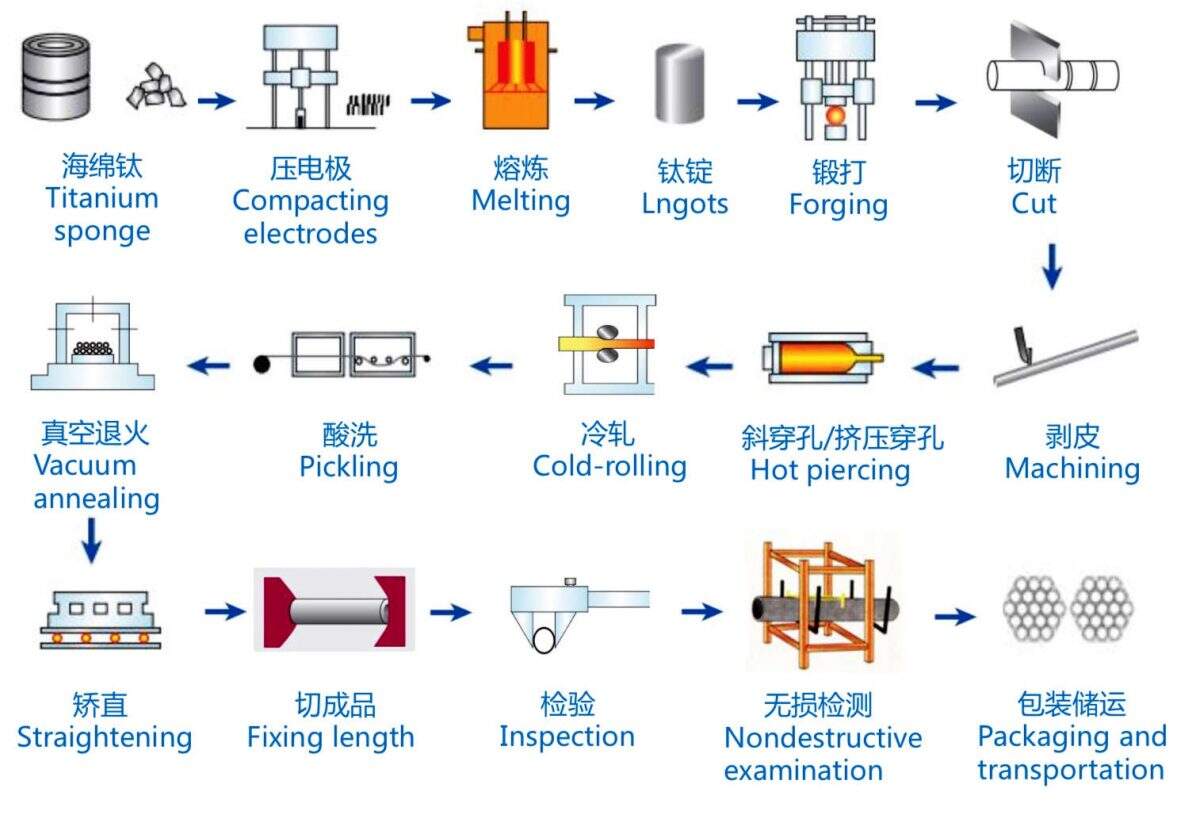

टाइटेनियम ट्यूब का उत्पादन प्रक्रिया: टाइटेनियम ट्यूबों का उत्पादन और संसाधन करने की एक विधि, यह संसाधन विधि इस प्रकार है: चरण 1: टाइटेनियम इनगोट को ट्यूब ब्लैंक में मोड़ना, और ट्यूब ब्लैंक पर सतह प्रतिबंध करना; चरण 2: सतह प्रतिबंध के बाद, ट्यूब ब्लैंक को पहली बार टाइटेनियम ट्यूब में रोल किया जाता है, और पहले रोलिंग के बाद तेल को हटाया जाता है; चरण 3: डिग्रीसिंग के बाद पहला पिकलिंग करें, पिकलिंग के बाद टाइटेनियम ट्यूब को धोयें, धोने के बाद सुखाएं, सुखाने के बाद अन्नायन करें, और अन्नायन के बाद टाइटेनियम ट्यूब को सीधा करें; चरण 4: टाइटेनियम ट्यूब को फिर से पिकलिंग करें। पिकलिंग के बाद, टाइटेनियम ट्यूब को धोयें, धोने के बाद टाइटेनियम ट्यूब को सुखाएं, और सुखाने के बाद टाइटेनियम ट्यूब को दूसरी बार रोल करें। रोल किए गए टाइटेनियम ट्यूब को फिनिश करने के लिए डिग्रीसिंग करें, डिग्रीसिंग के बाद पिकलिंग, पिकलिंग के बाद टाइटेनियम ट्यूब को धोएं, धोने और सुखाने के बाद, सुखाने के बाद अन्नायन, और अन्नायन के बाद टाइटेनियम ट्यूब को सीधा करें; चरण 5: सीधा करने के बाद टाइटेनियम ट्यूब को पिकलिंग करें, ऊपर दिए गए चरणों को दोहराएं, और छह बार रोलिंग के बाद फिनिश का उत्पाद प्राप्त करें

ऐल्यूमिनियम टेलीस्कोपिंग पोल।

स्टेनलेस स्टील कैपिलरी ट्यूब।

स्टेनलेस स्टील सेंसर ट्यूब।

ज़हांगजिआगंग चैनल इंटरनेशनल कंपनी लिमिटेड, जियांगसू प्रांत के आर्थिक रूप से विकसित क्षेत्र ज़हांगजिआगंग शहर के पूर्व में स्थित है। हमारी कंपनी में दो विभाग हैं - तकनीकी और उत्पादन विभाग और व्यापार विभाग। टाइटेनियम सामग्री और स्टेनलेस स्टील उत्पादों के अनुसंधान और विकास, उत्पादन और बाजार करण सेवाओं में विशेषज्ञता है।

फैक्ट्री विवरण कंपनी का उत्पादन फैक्ट्री परिसरों में स्थित है, अभी तक 200 लोगों की टीम है, फैक्ट्री क्षेत्र 100000 वर्ग मीटर है; कंपनी निर्यात क्षेत्र में बिक्री करती है, शहरी क्षेत्रों में ज़हांगजियागांग चैनल इंट'l को. लिमिटेड है, वर्तमान में 10 से 20 कर्मचारी हैं

प्रश्न: क्या आप एक कारखाना हैं या व्यापार कंपनी? ए. हम एक फैक्ट्री कंपनी हैं

प्रश्न: आप कैसे अपने उत्पादों की गुणवत्ता का विश्वास दिलाते हैं? उत्तर. ISO9000, ग्राहक की मांग, उत्पाद मानक, कच्चे माल, उत्पादन प्रक्रिया और अंतिम उत्पादों को नियंत्रित करने के लिए कठोर जाँच

प्रश्न: आप अपने उत्पादों के संबंध में समस्या कैसे हल करते हैं? उत्तर. जरूरत पड़ने पर सेवाएं: ग्राहकों की शिकायतों के लिए एक विशेष शिकायत-निपटान व्यवस्थित की जाती है, शिकायत के मुद्दों को पहली बार रिकॉर्ड किया जाता है और संबंधित जिम्मेदार व्यक्ति को प्रतिक्रिया और समाधान के लिए खोजा जाता है। विस्तृत जाँच हमारे 'गुणवत्ता सुधार कार्यवाही रिपोर्ट' में करें

प्रश्न: MOQ क्या है? उत्तर. सैंपल ऑर्डर स्वीकार्य है, और कुछ सैंपल मुफ्त हो सकते हैं

प्रश्न: आपको डिलीवरी के लिए कितना समय चाहिए?

1. 5-10 दिनों में स्टॉक लिस्ट में उपलब्ध प्रोडक्ट की आपूर्ति

2. साबुन प्रोडक्ट की मात्रा के अनुसार गणना की जरूरत है

प्रश्न: आपकी भुगतान शर्तें क्या हैं? उत्तर: टी/टी, एल/सी ऑन साइट, वेस्टर्न यूनियन

प्रश्न: हम आपकी कीमत कैसे प्राप्त कर सकते हैं? उत्तर: आपके लिए उद्धरण के लिए हमें नीचे दी गई जानकारी की आवश्यकता है:

1. उत्पाद का नाम

2. मानक

3. मातेरियल ग्रेड की रसायनिक संरचना

4. आयाम

5. मात्रा

6. विशेष भागों के लिए ड्राइंग