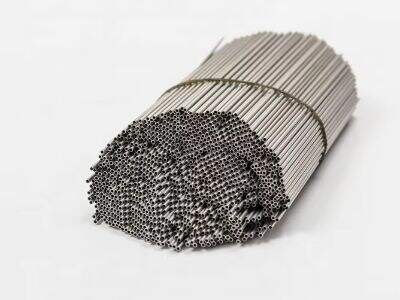

Titanium tubes are extremely strong and resilient tubes that can be utilized for a wide variety of applications. The metal used to make them is titanium, which comes strong and durable. This article will cover all you need to know about titanium tubes. This will help you determine whether they are a good fit for your needs and your projects.

Quare Titanium Tubuli magni

It helps make titanium tubes so great are incredible strengths. In reality, they are much more powerful compared to different sorts of materials like aluminum and steel. This strength means that titanium tubes are an excellent material choice for applications where strong materials are essential. If, for instance, you are constructing something that has to support a lot of weight or endure a lot of pressure, titanium tubes is an excellent choice.

That means they also have very low weight as well. They extruditur aluminium tube are very powerful, but also light, making them easy to lift and transport. They are a lot lighter so you can carry them without getting too tired and have to worry about moving around a lot for any jobs that need you to move a lot of material.

Besides also being strong and light, titanium tubes are very corrosion resistant. This means they're far less prone to rust or degradation over time compared to other metals. This allows them to wear for longer without the verification that they’ll need replacing, saving you money but also time in the future. Titanium tubes also work extremely well with extreme temperatures. Whether the temperature measured is sizzling hot or numbing cold, titanium tubes do not fail, which is why they are suitable for various applications.

Choosing the Correct Type of Titanium Tube

The first thing to know is that when buying titanium, you have a variety of different types or grades to choose from, so you should pick the right one for your needs. Depending on the type of titanium, some are more expensive and some are more appropriate for specific applications. Titanium grade 2 is the most widely used titanium grade and is an excellent compromise between cost, corrosion resistance, and mechanical properties. Compared to Grade 1, however, Grade 5 titanium is much more solid and is great for material uses where strength is important, such as in aerospace at particular components.

quod ferrule polus tentorium performance of a titanium tube for your application can be drastically affected by selecting the correct grade of titanium tube. When talking about grades, it is crucial to exercise caution and partner with a trusted supplier who can educate you on the various grades and assist you in choosing the right one for you! Channel provides a comprehensive selection of titanium tubes, available in different grades so you can obtain the right product for your intended application.

Where Titanium Tubes are Used

But where, you may ask, are titanium tubes actually being used? They instructa aluminium tube are appearing in various industries and have numerous uses. They are mainly used in: aerospace (in airplanes and space vehicles), medical devices(in hospital tools and equipment), industrial equipment (in machinery), sporting goods (in bicycles and golf clubs).

Titanium tubes are commonly used in these types of applications, as they are strong, durable, and resistant to corrosion. It allows them to withstand hard conditions and remain durable, which is crucial for safety and reliability across these sectors.

How to Handle a Titanium Tube

If you are working with titanium tubes, especially when joining them by welding, I have a few words of advice. Now why won, t you stick to other metals: You need to be very careful at the time of welding because titanium become might contaminated when it comes in contact with other metals. That contamination can weaken the titanium and make it less effective. For this reason, one must use clean tools, ensuring that the titanium does not touch any other metal during the weld.

Additionally, the titanium tubes require a complex surface finishing process due to the high corrosion resistance characteristics of titanium. To involve professional tools and techniques to ensure that the finish is smooth and even, So, the tubes sound good, and they look good.

Titanium tubes are a specialty for our team of experts at Channel and they have years of experience managing these orders. We can also advise you on fabrication, welding and finishing best practices, to make sure you do it right.

Taking Care of Titanium Tubes

If you have selected the right type of titanium tube for your requirements, you need to ensure your care of the tube. This means cleaning regularly and performing maintenance to avoid corrosion and make sure the material stays strong and durable in the long term. Titanium tubes must be kept in a dry and safe place 20 dec; 2021 image/product Influence of environment on physical properties of metal; The titanium shall be stored at a dry place.

Channel guides you on the best way of maintaining and caring for your titanium tubes. This can help keep them operating well and extend their life so you can get the most bang for your buck.

In summary, titanium tubes are ideal for a variety of applications due to their strength, durability, and corrosion resistance. Selecting the correct titanium grade for your needs, as well as proper maintenance during its lifetime, are crucial factors that help ensure titanium will last. Channel offers an extensive selection of titanium tubes and expertise on best practices for fabrication, welding, finishing and maintenance. One such way to know more about titanium tubes will allow you to take educated decisions about your projects and make the most out of it.