Name |

Titanium Tube & Pipe |

|

Standard |

ASTM B338/ASME SB338, ASTM B337/ASME SB337, ASTM B861/ASME SB861, ASTM B862/ASME SB862, AMS4911, AMS4928 |

|

Material Grade |

Gr1, Gr2, Gr4, Gr7, Gr9, Gr11, Gr12, etc |

|

Length |

≤14000mm |

|

Size mm |

Diameter 3-508mm |

|

Section shape |

Round / Square |

|

Tolerance |

a) Outer Diameter: +/- 0.01mm |

|

b) Thickness: +/- 0.01mm |

||

c) Length: +/- 0.1mm |

||

Surface |

Pickling, annealing, polishing, bright |

|

Feature |

1. Low Density and High Strength 2. Excellent Corrosion Resistance 3. Good resistance to effect of heat 4. Excellent Bearing to cryogenic property 5. Nonmagnetic and Non-toxic 6. Good thermal properties 7. Low Modulus of Elasticity |

|

Test |

Squash test, extended test, water pressure test, crystal rot test, heat treatment, NDT |

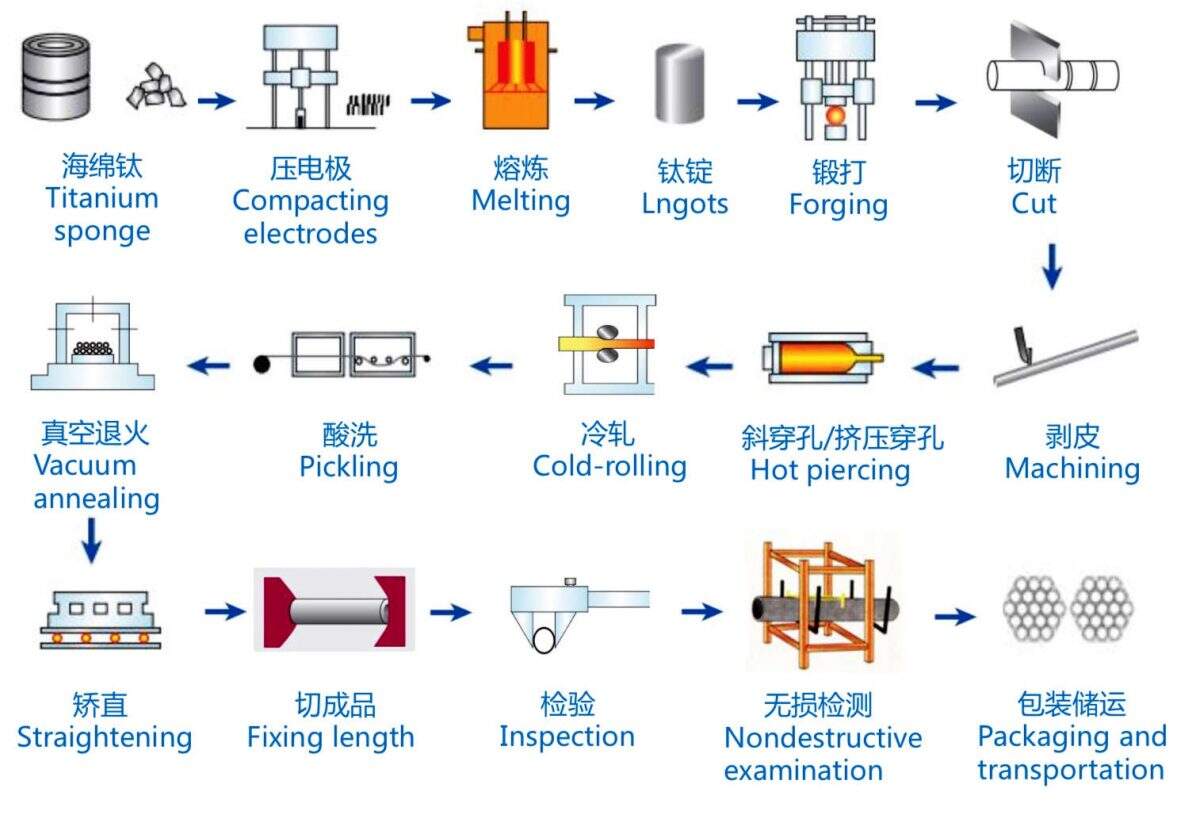

A method for producing and processing titanium tubes, the processing method is as follows:

Step 1: Forging the titanium ingot into a tube blank, and performing surface treatment on the tube blank; Step 2: After the surface treatment, the tube blank is rolled into a titanium tube for the first time, and the oil is removed after the first rolling;

Step 3: Carry out the first pickling after degreasing, wash the titanium tube after pickling, dry it after washing, annealing after drying, and straighten the titanium tube after annealing;

Step 4: Pickling the titanium tube again. After the pickling, rinse the titanium tube, dry the titanium tube after washing, and then roll the titanium tube for the second time after drying. The rolled titanium tube The finished product is degreasing, pickling after degreasing, washing the titanium tube after pickling, washing and drying, annealing after drying, and straightening the titanium tube after annealing;

Step 5: Pickling the titanium tube after straightening, repeat the above steps, and obtain the finished product after six times of rolling

channel

Presenting the ASTM B348 Ti 6Al 4V Seamless GR5 Titanium Tube/Pipe from Channel - the option is high-performance that ideal that want exceptional power, durability, and corrosion opposition.

Made from premium grade materials that stick to strict ASTM B348 standards quality is dependability that ensuring will trust.

Made of titanium alloy this tube/pipe offers strength-to-weight is making this ideal that impeccable demanding applications in aerospace medical and protection companies. The trend is fluid that seamless is efficient and decreases the probability of leaks while the Gr5 titanium alloy provides exemplary opposition to high conditions extreme pressures and chemical corrosion.

Can be had in a number of sizes to satisfy demands that are specific. You covered whether you shall need modified sizes or proportions that can easily be standard has got. Using dedication to providing top-quality products and services and customer is exemplary you're going to be assured you are getting the significance is way better when it comes to difficult money this gained.

Installing is really a piece of cake due to its seamless design. Perfect installation is simple virtually any application making it a choice that perfect OEMs fabricators and fix solutions.

Channel is simply a brand name this trusted due to its items are top-quality meet or exceed industry standards. They pride by themselves on supplying consumer is exceptional and customer care is ensuring. They provide a variety is vast of items and add-ons to generally meet the desires of the clients and gives value is price that unbeatable.

Today Order yours and feel the performance and durability of titanium.