Presenting, customized fabricated closed end sensor tube for temperature sensor machine.

Are you tired and sick of dealing with standard sensor pipes which do not fit your preferences? Look absolutely no further than customized fabricated closed end sensor tube for temperature sensor machine. Our pipes are available especially to suit your heat sensor devices, ensuring accurate and dependable readings each time.

Our sensor pipes are completely customizable to suit your unique requirements. We provide a number of lengths and materials to pick from, including metal copper stainless. Our specialist fabrication group could also accommodate unique needs and diameter change or extra threading.

Among the key highlights of our sensor pipes is their end closed design. This means that the sensor is completely protected from outside contaminants, like dampness or dirt. It will help make certain that your heat readings are accurate and constant, even yet in harsh or dirty surroundings.

Our sensor pipes are extremely an easy task to install. Just slip the pipe on the sensor, connect the appropriate fixtures and you're all set. Our pipes are manufactured to suit snugly to your sensor, making sure there's absolutely no motion or sliding during usage.

At Channel, we pride ourselves on our dedication to quality. Our sensor pipes are tested and manufactured to your greatest industry criteria, making sure you obtain something actually safe and dependable. Our pipes is also supported by a comprehensive guarantee, providing you satisfaction knowing that your investment is protected.

Channel

As an experienced metal tube supplier, specialized in titanium tubes, aluminum tubes, stainless steel tubes, and also can supply the whole production line for factory

Stainless Steel Capillary Pipe / Tube

Stainless steel capillary pipe / tube: it has good wear resistance, corrosion resistance, tensile resistance, softness, water resistance, high temperature resistance and excellent electromagnetic shielding performance As a raw material, stainless steel capillary pipe / tube is widely used in medical treatment, petroleum, aerospace, medical equipment, air conditioning, chemical industry, electronics, accessories, kitchen appliances, food machinery, power generation, pharmaceutical, water supply equipment, boilers and other fields

|

Model

|

Stainless Steel Capillary Tubes / Pipes

|

|

|

|

|

|

Standard

|

ASTM, ASME, EN, JIS, DIN, GB/T etc

|

|

|

|

|

|

Material Grade

|

304(0Cr18Ni9)

304L(00Cr18Ni10)

316(0Cr17Ni12Mo2)

316L(0Cr17Ni14Mo2)

321, 409, 409L, 430

|

|

|

|

|

|

Diameter

|

a) Outer Diameter: 0.1mm-80mm

|

|

|

|

|

|

b) Wall Thickness: 0.05mm-2.0mm

|

|

|

|

|

c) Length: ≤6000mm Or in coil

|

|

|

|

|

Tolerance

|

a) Outer Diameter: +/- 0.01mm~+/- 0.5mm

|

|

|

|

|

|

b) Thickness: +/- 10% or as your request

|

|

|

|

|

c) Length: +/- 1mm or as your request

|

|

|

|

|

Surface Treatment

|

Polishing, Annealing, Mirro surface, Bright, Pickling

|

|

|

|

|

|

Type

|

Welded, Seamless

|

|

|

|

|

|

Shape

|

Round, Square, Irregular

|

|

|

|

|

|

Application

|

medical treatment, petroleum, aerospace, medical equipment, air conditioning, chemical industry, electronics, accessories, food machinery, power generation, pharmaceutical and other fields

|

|

|

|

|

|

Packaging

|

In bundles with waterproof material, in wooden cases

Please send details packing to us if you have other requirements

|

|

|

|

|

High Precision

Shining Surface

Clean Inner Wall

No Burr

Support Custom Processing:

CNC Machining Center

EDM

Wire Cutting machines etc

Support for processing special-shaped capillaries. Processing range: precision tube cutting, chamfering, tube expansion, tube shrinkage, side hole, sealing (round or flat), coil, thread, bending, etc

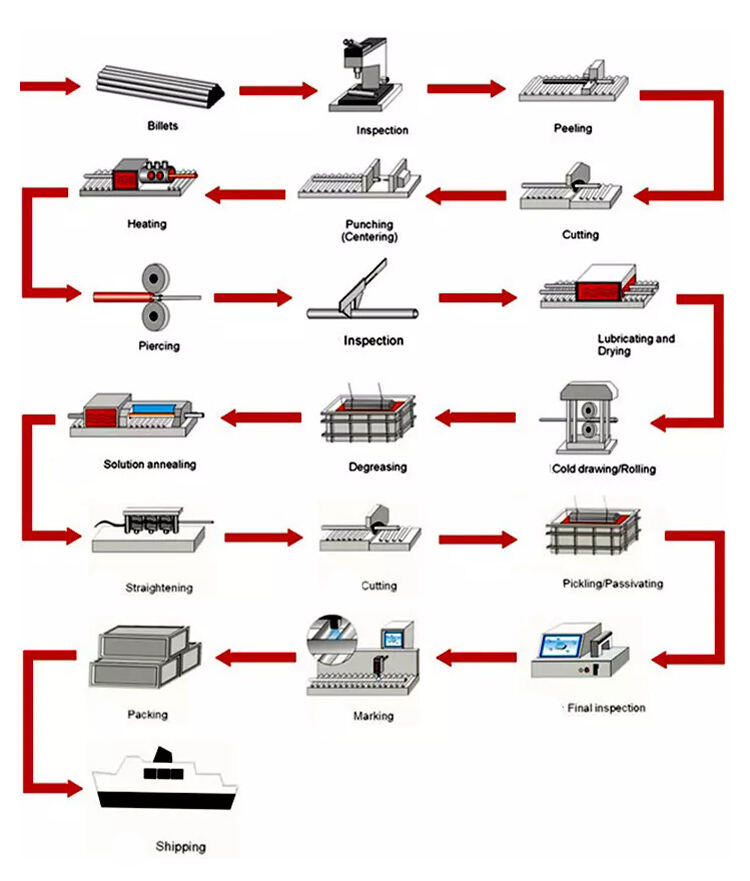

Stainless steel welded pipe production process:

Raw material - silting - welding pipe - trimming - polishing - inspection (spray printing) - packaging - shipping (warehouse) (decorative welded pipe). Raw material - Slitting - Welding pipe Heat treatment - Correction - Straightening - End trimming - Pickling - Water pressure test - Inspection (printing) - Packaging - Shipping (warehouse) Pipe for industrial piping of welded pipe

Zhangjiagang Channel int'l Co, LTD

Zhangjiagang Channel int'l Co, LTD is located the East of economically developed region-- Zhangjiagang city Jiangsu province. our company has two departments-technical & producing department and trade department. in titanium materials and stainless steel products research and development, production and marketing series

Factory description

Company production factory is located in the suburbs, now has a staff of 200 people, plant area of 100000 square meters, Company sales in the export sector, zhangjiagang Channel intl co. Itd in urban areas, the existing staff 10 to 20 people

Q. Are you a factory or trading company

A. We are a factory company

Q. How to ensure the quality of your products

A. IS09000, client requirements, product standards, strict inspection to control raw material, production process and final products

Q. How do you resolve the problem about your products

A. Person of aging services: For customer complaints commissioner set up a special complaint handling, complaint issues recorded the first time and find the relevant person in charge of the feedback and resolve. Details check our "Quality corrective action report"

Q. What is the MOQ

A. Sample order is acceptable, And some samples can be free

Q. How long do you need the delivery time

1) Supply within 5-10 days (product in our Stock list)

2) Custom products need to be calculated according to the quantity

Q. What 's your payment terms

A. T/T, L/C at sight, Western Union

Q. How can we get your price

A. We need below information to quote for you:

1. Product Name

2. Standard

3. Material Grade Chemical Composition

4. Dimension

5. Quantity

6. The Drawing for Special Parts