Name |

Titanium Tube & Pipe |

|

Standard |

ASTM B338/ASME SB338, ASTM B337/ASME SB337, ASTM B861/ASME SB861, ASTM B862/ASME SB862, AMS4911, AMS4928 |

|

Material Grade |

Gr1, Gr2, Gr4, Gr7, Gr9, Gr11, Gr12, etc |

|

Length |

≤14000mm |

|

Size mm |

Diameter 3-508mm |

|

Section shape |

Round / Square |

|

Tolerance |

a) Outer Diameter: +/- 0.01mm |

|

b) Thickness: +/- 0.01mm |

||

c) Length: +/- 0.1mm |

||

Surface |

Pickling, annealing, polishing, bright |

|

Feature |

1. Low Density and High Strength 2. Excellent Corrosion Resistance 3. Good resistance to effect of heat 4. Excellent Bearing to cryogenic property 5. Nonmagnetic and Non-toxic 6. Good thermal properties 7. Low Modulus of Elasticity |

|

Test |

Squash test, extended test, water pressure test, crystal rot test, heat treatment, NDT |

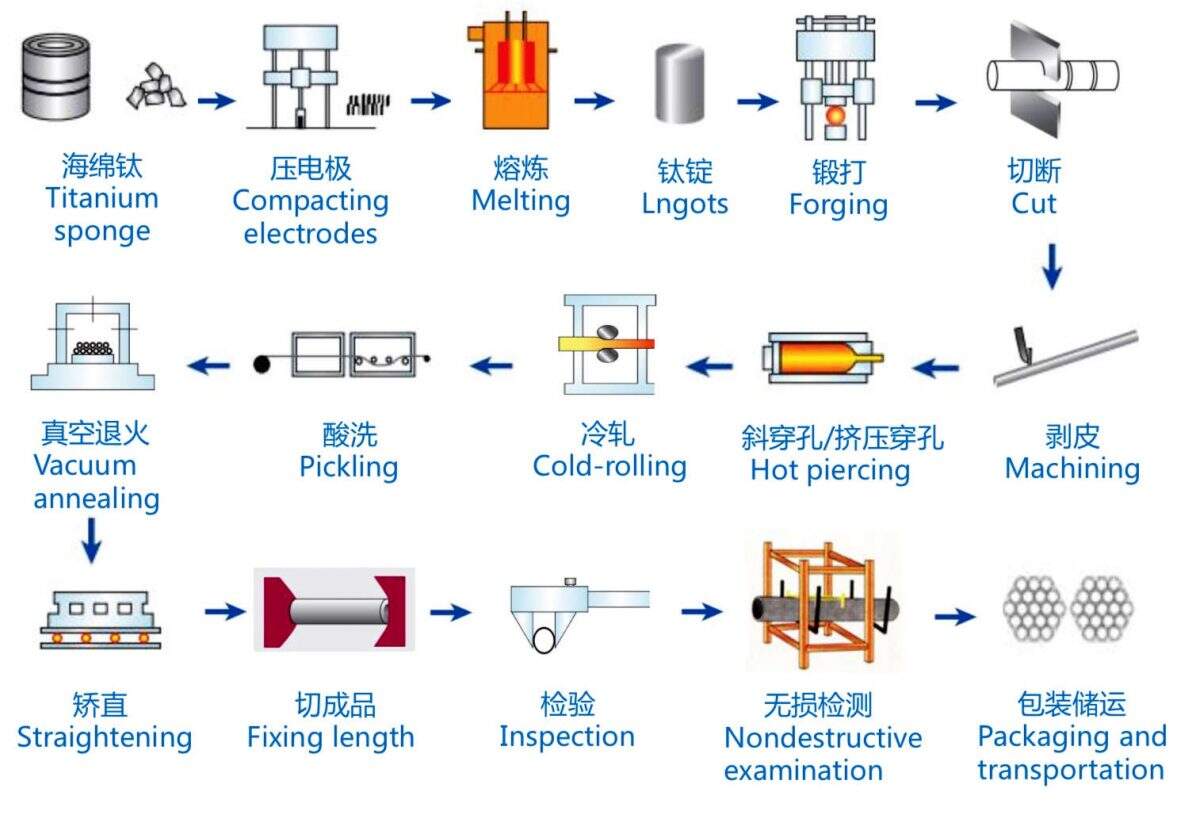

A method for producing and processing titanium tubes, the processing method is as follows:

Step 1: Forging the titanium ingot into a tube blank, and performing surface treatment on the tube blank; Step 2: After the surface treatment, the tube blank is rolled into a titanium tube for the first time, and the oil is removed after the first rolling;

Step 3: Carry out the first pickling after degreasing, wash the titanium tube after pickling, dry it after washing, annealing after drying, and straighten the titanium tube after annealing;

Step 4: Pickling the titanium tube again. After the pickling, rinse the titanium tube, dry the titanium tube after washing, and then roll the titanium tube for the second time after drying. The rolled titanium tube The finished product is degreasing, pickling after degreasing, washing the titanium tube after pickling, washing and drying, annealing after drying, and straightening the titanium tube after annealing;

Step 5: Pickling the titanium tube after straightening, repeat the above steps, and obtain the finished product after six times of rolling

channel

Titanium alloy threaded tubes machined with accuracy and built to endure. These pipes are constructed with top-quality titanium alloy and generally are accessible in three grades being Gr2 is different, and Gr9 - each utilizing their very own unique properties and benefits.

Recognized for the exemplary corrosion resistance making it a choice is use that chemical is popular marine applications. It is usually extremely ductile and incredibly super easy to weld making this an option is production this fantastic. The Gr5 grade of titanium alloy in addition has higher energy and durability making it ideal for present in aerospace and applications being automotive. Finally the Gr9 grade of titanium alloy is a ground this middle that superb a balance of strength and corrosion opposition which makes it versatile and widely found in a number of applications.

Not just the materials are top-quality create these tubes be noticed - additionally it is the precision machining and threading that ensure a fit time is ideal. Our state-of-the-art CNC machines and specialists being skilled capable of making tubes that do not just look great but also function flawlessly. The threads are cut to specs that are exacting for simple installation and an internet link is safe.

Whether you are caring for a custom motorcycle develop creating an aircraft is experimental simply require a high-quality pipe that threaded the commercial application Channel's titanium alloy threaded pipelines will be the choice is perfect. The mixture of top-quality materials accuracy professional and machining threading make for a product is actually reliable and effortless to work with.

So why choose Channel? First of all we have a long time of expertise available in the market and a track record of producing quality items. We just make use of the most materials are useful the technology is latest to ensure our products and services meet or surpass your expectations. Plus we provide competitive prices and distribution is fast require quickly along with a the value that best to get the parts.

If you should be trying to find a titanium that is high-quality is threaded pipe CNC machined to perfection look no further than Channel. Our Gr2 Gr5 and Gr9 threaded tubes is the option this ideal an array of applications and our dedication to client and quality satisfaction make us the premier choice for companies and folks alike.