|

Description

|

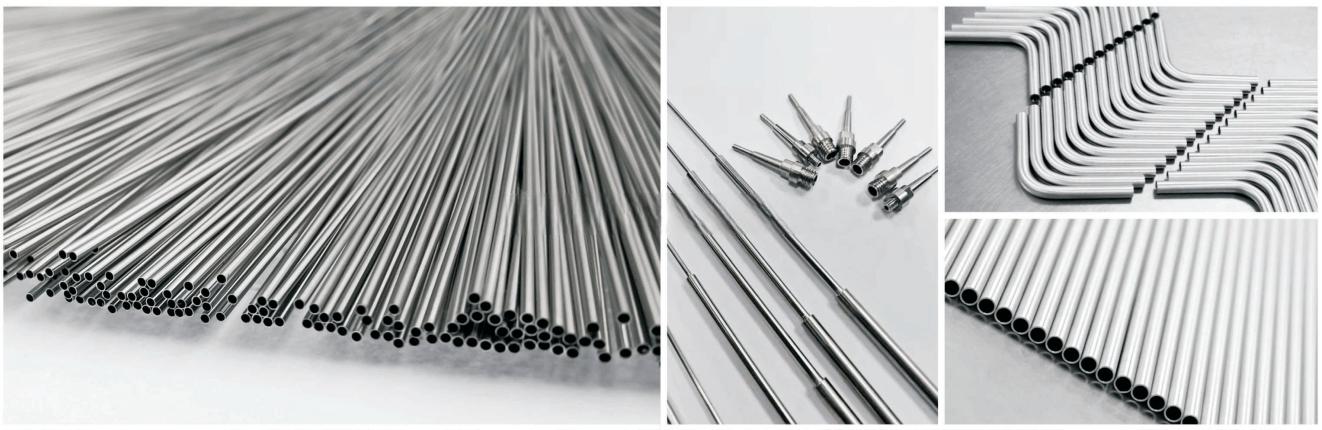

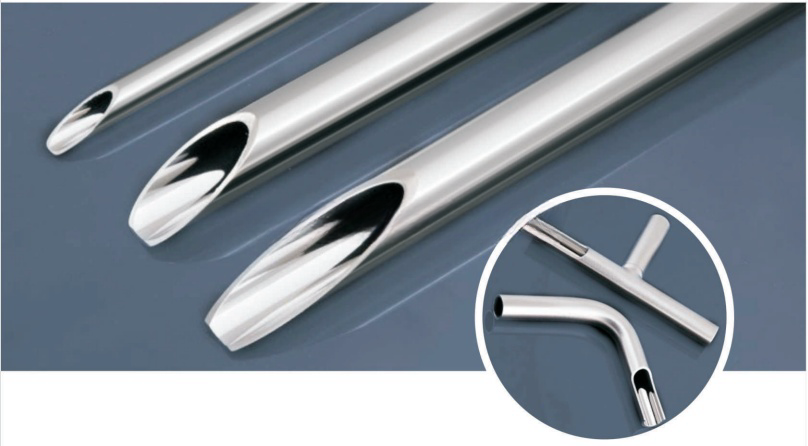

stainless steel tube one end round closed

|

|

|

Supply Capacity

|

300 tons/year

|

|

|

Process Method

|

cold drawn and cold rolled

|

|

|

Out Diameter

|

0.2mm-6mm

|

|

|

Wall Thickness

|

0.02mm-2mm

|

|

|

Length

|

1mm -3000mm

|

|

|

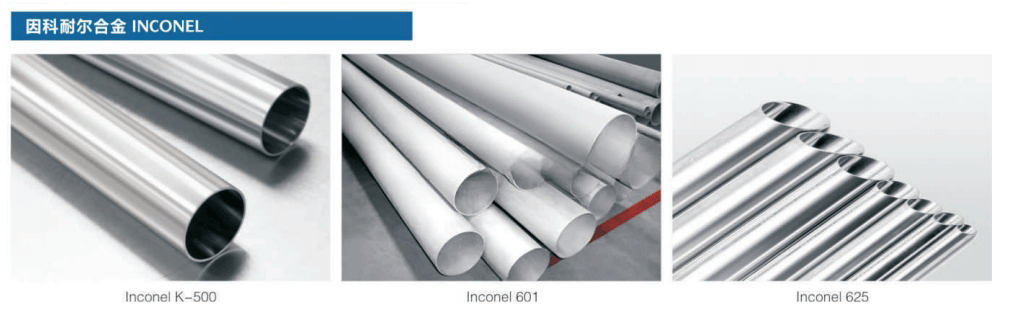

Steel Grade

|

200 (Ni: 0.8%), 201B (Ni: 3%), 201H (Ni: 5%)

|

|

|

301 (Ni: 6%), 304, TP304, TP304L/304L, 321, TP321, 316, TP316L, 316L, 316Ti

|

||

|

317, 317L, 309S, 310S(2520), 347, Duplex 2205, Duplex 2207, Inconel 600, 625, 718 etc.

|

||

|

Standards

|

ASTM / ASME, GB, DIN, JIS, EN, etc.

|

|

|

Application

|

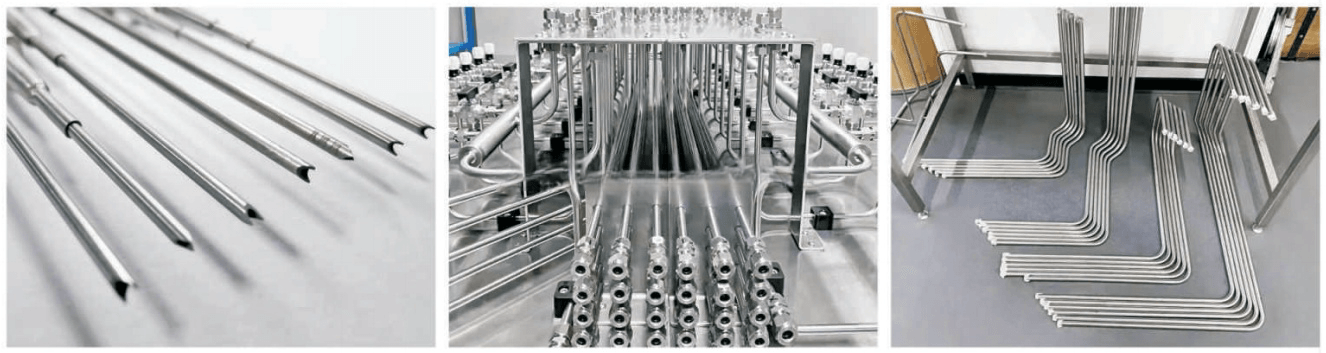

Surgical instruments, Water and sewage treatment, Sensor pipe, etc.

|

|

|

Packing |

1. with plastic cap to protect both ends

|

|

|

2. plastic bag wrapped outside the pipe

|

||

|

3. bundles to be covered by polythene & strapped securely.

|

||

|

4. if require, then pack into wooden box.

|

||

|

Certification

|

ISO 9001: 2008

|

|

|

Delivery time

|

5-30 days depend on Quantity

|

|

|

Payment Term

|

T/T, Irrevocable L/C at sight

|

|

|

Trade Term

|

FOB, CFR, CIF

|

|

Chemical Composition(%) |

201

|

202

|

304

|

316

|

S31803

|

S32750

|

||

|

C

|

≤0.15

|

≤0.15

|

≤0.08

|

≤0.08

|

≤0.030

|

≤0.030

|

||

|

Si

|

≤1.00

|

≤1.00

|

≤1.00

|

≤1.00

|

≤1.00

|

≤0.80

|

||

|

Mn

|

5.5-7.5

|

7.5-10.0

|

≤2.00

|

≤2.00

|

≤2.00

|

≤1.20

|

||

|

P

|

≤0.060

|

≤0.060

|

≤0.045

|

≤0.045

|

≤0.030

|

≤0.035

|

||

|

S

|

≤0.030

|

≤0.030

|

≤0.030

|

≤0.030

|

≤0.020

|

≤0.020

|

||

|

Cr

|

16-18

|

17-19

|

18-20

|

16-18

|

21-23

|

21-23

|

||

|

Ni

|

3.5-5.5

|

4.0-6.0

|

8.0-10.5

|

16.0-18.5

|

4.5-6.5

|

6.0-8.0

|

||

|

Mo

|

2.0-3.0

|

2.5-3.5

|

3.0-5.0

|

|||||

|

N

|

≤0.25

|

≤0.25

|

0.08-0.2

|

0.24-0.32

|

||||

|

Cu

|

≤0.50

|

|||||||

|

Mechanical Property |

Tensile Strength(MPa)

|

≥655

|

≥620

|

≥515

|

≥515

|

≥620

|

≥800

|

|

|

Yeild Strength(MPa)

|

≥260

|

≥310

|

≥205

|

≥205

|

≥450

|

≥550

|

||

|

Elongation(%)

|

≥35

|

≥35

|

≥35

|

≥35

|

≥25

|

≥15

|

||

|

Hardness(HV)

|

≤230

|

≤230

|

≤200

|

≤200

|

≤303

|

≤323

|

|

Application

|

Architectural/Civil Engineer

|

Door and window fittings, steel furniture, structural sections etc.

|

|||||

|

Transport

|

Exhaust systems, car trim, road tankers, ship containers, ships chemical tankers etc.

|

||||||

|

Chemical/Pharmaceutical

|

Pressure vessels, process piping etc.

|

||||||

|

Oil & Gas

|

Platform accomodation, cable wires, subsea pipelines etc.

|

||||||

|

Water

|

Water and sewage treatment, water tubing, hot water tankers etc.

|

||||||

|

Medical

|

Surgical instruments, surgical implanets, MRI scanners etc.

|

||||||

|

Food & Drink

|

Catering equipment, brewing, food processing etc.

|

||||||

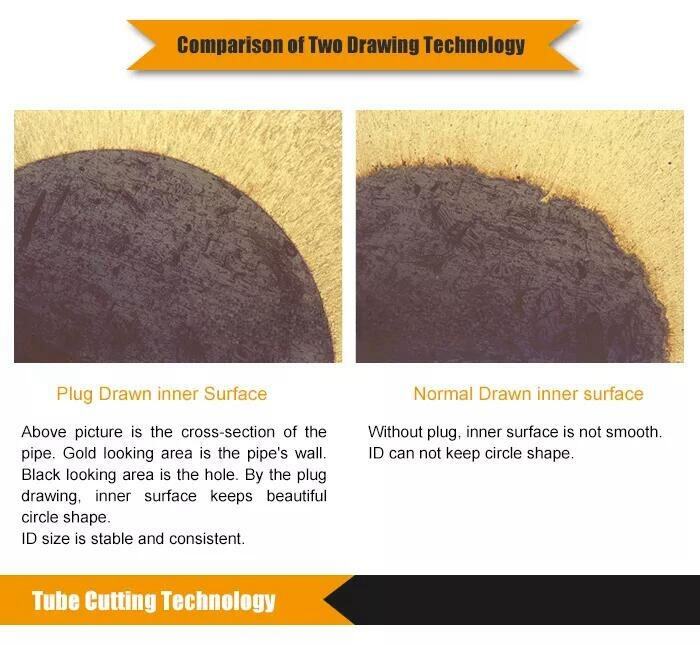

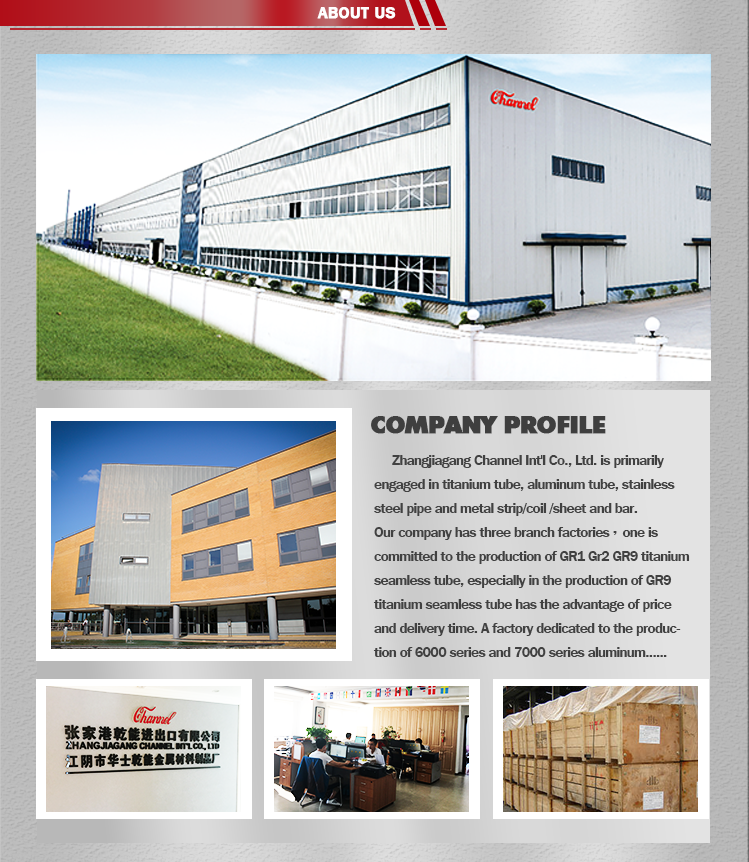

Introducing Channel's Micro 304 316 Stainless Steel Capillary Tube, a top-quality product designed to meet the needs of various industries such as medical, automotive, and aerospace. Made of premium-grade stainless steel, Channel's capillary tube offers excellent corrosion resistance, durability, and longevity for long-lasting performance in your applications.

Supplies a smooth internal area for enhanced movement rates, rendering it perfect for fluid applications needing exact and accurate fluid control by having a seamless construction. The pipe's slim and narrow diameter enables higher pressure ranks, ensuring efficient and fluid transfer is constant. Additionally, the capillary tube's high-purity stainless steel contamination, which makes it ideal for used in critical applications.

Come in different lengths and diameters, giving our clients freedom and customization choices to satisfy their specifications being unique. Our capillary pipe can be easily welded, bent, and cut to size, which makes it simple and convenient to set up in tight areas.

Perfect for medical applications because of its properties being high-quality. The tube's smooth area is internal its appropriate use in catheters, needles, along with other fluid transfer devices, where precision and accuracy are paramount. Suitable into tight motor compartments, ensuring consistent fluid flow to critical systems such as brake system and energy steering in automotive applications. Likewise, in aerospace applications, the capillary tube's high-pressure rating and properties which can be corrosion-resistant it well suited for use in hydraulic and gas transfer systems.

Channel's Micro is a high-quality product that meets the needs of various industries worldwide.