Launching, the micro 316 stainless steel capillary tube for electronic sensor the ideal solution to all your electronic sensor applications!

Manufactured with high-grade 316 stainless steel, this capillary pipe was created to withstand perhaps the most challenging ecological conditions. From extreme conditions to corrosive surroundings, you can depend on this pipe to supply dependable and accurate information with no deterioration.

Measuring only some millimeters in diameter, it provides the perfect dimension for a number of applications. The micro 316 stainless steel capillary tube for electronic sensor ensures accurate heat and stress readings whether you're working together with force sensors or thermocouples.

This top-quality capillary is simple to install and flexible, allowing it to match even the tightest areas without compromising its durability. Plus, its bendable nature eliminates the need for connectors, rendering it an economical answer to sensor electronic.

But that isn't all - the micro 316 stainless steel capillary tube for electronic sensor was engineered to also present very good responsiveness. Having its small diameter, you can very quickly identify any change in force or heat, making certain your sensors will react quickly and accurately.

Whether you are employed in the automotive or aerospace industry, or desire a dependable solution for your commercial gear, the micro 316 stainless steel capillary tube for electronic sensor is the ideal option.

Utilising the Channel name brand's dedication to quality and innovation, you'll be able to trust that this capillary pipe is the greatest in its course. So, why select others? Invest in to the micro 316 stainless steel capillary tube for electronic sensor and experience the advantages of dependability, freedom, and precision

Channel

As an experienced metal tube supplier, specialized in titanium tubes, aluminum tubes, stainless steel tubes, and also can supply the whole production line for factory

★★★ One is committed to the production of 6000 series and 7000 series

aluminum tube, especially in the production of 7001, 7005, 7075 aluminum tent pole pipe and arrow tube has many advantages

★★★ One is committed to the production of

stainless steel seamless and welded pipe, especially in the production of various kinds of medical stainless steel capillary pipe

★★★ One is committed to the production of GR1 GR2 GR9

titanium seamless tube, especially in the production of GR9 titanium seamless tube has the advantage of price and delivery time

Stainless Steel Capillary Pipe / Tube

Stainless steel capillary pipe / tube: it has good wear resistance, corrosion resistance, tensile resistance, softness, water resistance, high temperature resistance and excellent electromagnetic shielding performance As a raw material, stainless steel capillary pipe / tube is widely used in medical treatment, petroleum, aerospace, medical equipment, air conditioning, chemical industry, electronics, accessories, kitchen appliances, food machinery, power generation, pharmaceutical, water supply equipment, boilers and other fields

|

Model

|

Stainless Steel Capillary Tubes / Pipes

|

|

|

|

|

|

Standard

|

ASTM, ASME, EN, JIS, DIN, GB/T etc

|

|

|

|

|

|

Material Grade

|

304(0Cr18Ni9)

304L(00Cr18Ni10)

316(0Cr17Ni12Mo2)

316L(0Cr17Ni14Mo2)

321, 409, 409L, 430

|

|

|

|

|

|

Diameter

|

a) Outer Diameter: 0.1mm-80mm

|

|

|

|

|

|

b) Wall Thickness: 0.05mm-2.0mm

|

|

|

|

|

c) Length: ≤500mm Or in coil

|

|

|

|

|

Tolerance

|

a) Outer Diameter: +/- 0.01mm

|

|

|

|

|

|

b) Thickness: +/- 0.01mm

|

|

|

|

|

c) Length: +/- 0.1mm

|

|

|

|

|

Surface Treatment

|

Polishing, Annealing, Mirro surface, Bright, Pickling

|

|

|

|

|

|

Type

|

Welded, Seamless

|

|

|

|

|

|

Shape

|

Round, Square, Irregular

|

|

|

|

|

|

Application

|

medical treatment, petroleum, aerospace, medical equipment, air conditioning, chemical industry, electronics, accessories, food machinery, power generation, pharmaceutical and other fields

|

|

|

|

|

|

Packaging

|

In bundles with waterproof material, in wooden cases

Please send details packing to us if you have other requirements

|

|

|

|

|

Support for processing special-shaped capillaries. Processing range: precision tube cutting, chamfering, tube expansion, tube shrinkage, side hole, sealing (round or flat), coil, thread, bending, etc

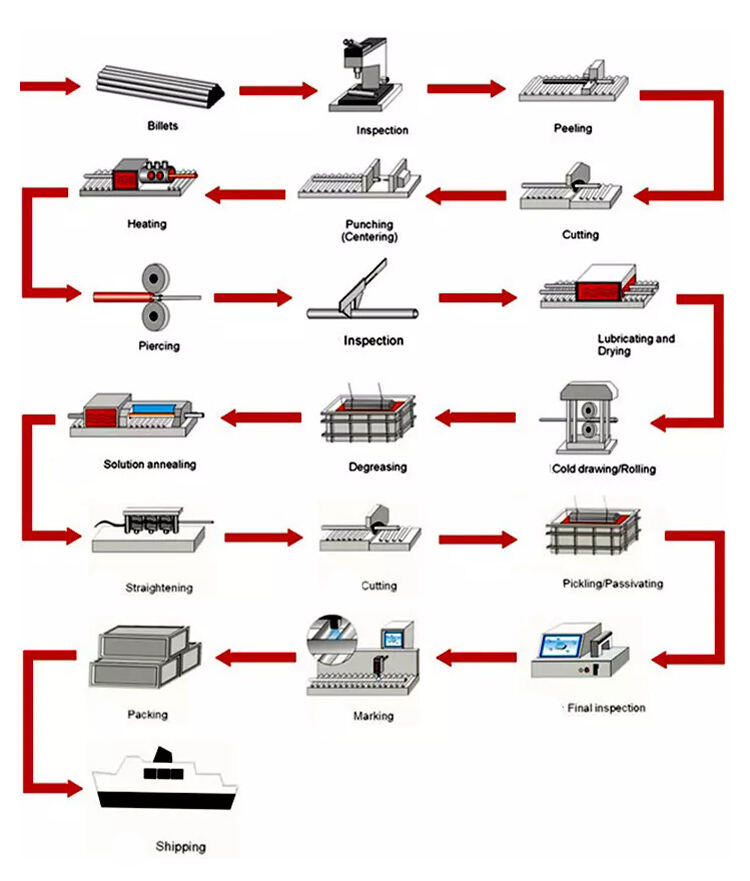

Stainless steel welded pipe production process:

Raw material - silting - welding pipe - trimming - polishing - inspection (spray printing) - packaging - shipping (warehouse) (decorative welded pipe). Raw material - Slitting - Welding pipe Heat treatment - Correction - Straightening - End trimming - Pickling - Water pressure test - Inspection (printing) - Packaging - Shipping (warehouse) Pipe for industrial piping of welded pipe

Zhangjiagang Channel int'l Co, LTD

Zhangjiagang Channel int'l Co, LTD is located the East of economically developed region-- Zhangjiagang city Jiangsu province. our company has two departments-technical & producing department and trade department. in titanium materials and stainless steel products research and development, production and marketing series

Factory description

Company production factory is located in the suburbs, now has a staff of 200 people, plant area of 100000 square meters, Company sales in the export sector, zhangjiagang Channel intl co. Itd in urban areas, the existing staff 10 to 20 people

Q. Are you a factory or trading company

A. We are a factory company

Q. How to ensure the quality of your products

A. IS09000, client requirements, product standards, strict inspection to control raw material, production process and final products

Q. How do you resolve the problem about your products

A. Person of aging services: For customer complaints commissioner set up a special complaint handling, complaint issues recorded the first time and find the relevant person in charge of the feedback and resolve. Details check our "Quality corrective action report"

Q. What is the MOQ

A. Sample order is acceptable, And some samples can be free

Q. How long do you need the delivery time

1) Supply within 5-10 days (product in our Stock list)

2) Custom products need to be calculated according to the quantity

Q. What 's your payment terms

A. T/T, L/C at sight, Western Union

Q. How can we get your price

A. We need below information to quote for you:

1. Product Name

2. Standard

3. Material Grade Chemical Composition

4. Dimension

5. Quantity

6. The Drawing for Special Parts