Name |

Titanium Tube & Pipe |

|

Standard |

ASTM B338/ASME SB338, ASTM B337/ASME SB337, ASTM B861/ASME SB861, ASTM B862/ASME SB862, AMS4911, AMS4928 |

|

Material Grade |

Gr1, Gr2, Gr4, Gr7, Gr9, Gr11, Gr12, etc |

|

Length |

≤14000mm |

|

Size mm |

Diameter 3-508mm |

|

Section shape |

Round / Square |

|

Tolerance |

a) Outer Diameter: +/- 0.01mm |

|

b) Thickness: +/- 0.01mm |

||

c) Length: +/- 0.1mm |

||

Surface |

Pickling, annealing, polishing, bright |

|

Feature |

1. Low Density and High Strength 2. Excellent Corrosion Resistance 3. Good resistance to effect of heat 4. Excellent Bearing to cryogenic property 5. Nonmagnetic and Non-toxic 6. Good thermal properties 7. Low Modulus of Elasticity |

|

Test |

Squash test, extended test, water pressure test, crystal rot test, heat treatment, NDT |

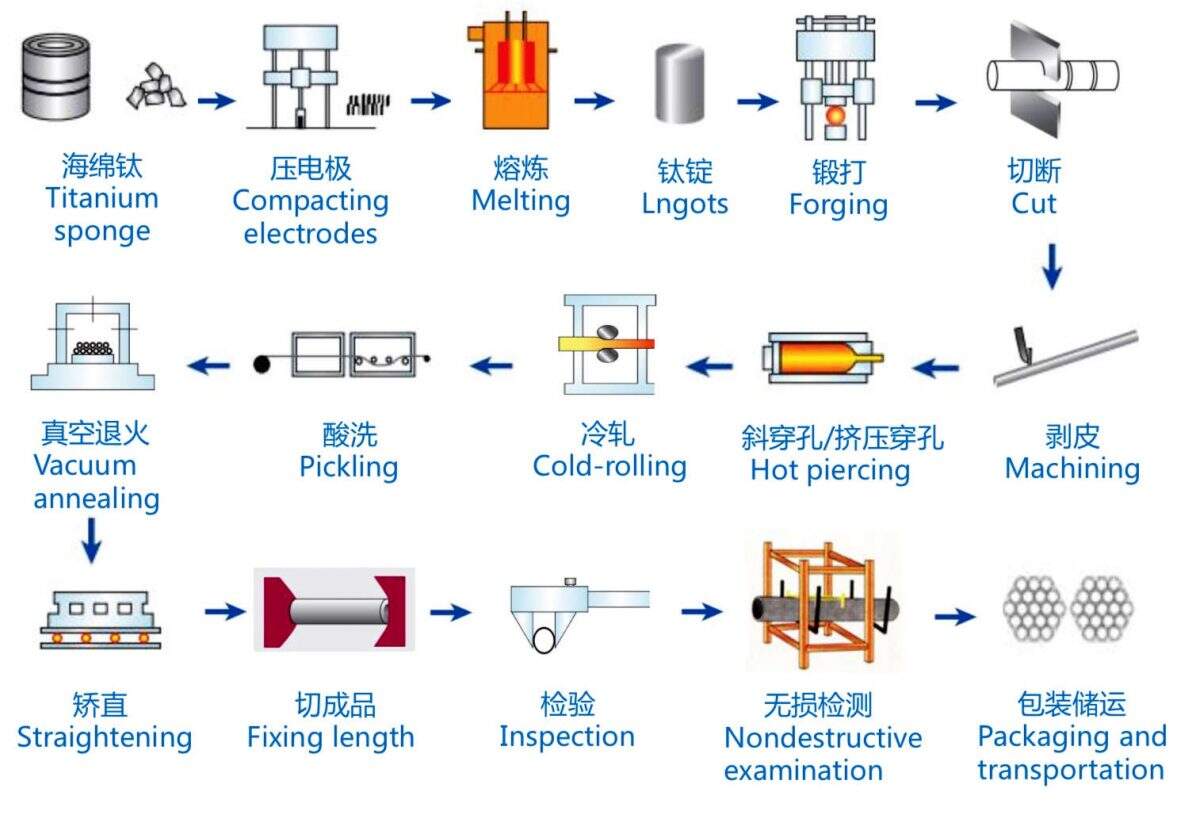

A method for producing and processing titanium tubes, the processing method is as follows:

Step 1: Forging the titanium ingot into a tube blank, and performing surface treatment on the tube blank; Step 2: After the surface treatment, the tube blank is rolled into a titanium tube for the first time, and the oil is removed after the first rolling;

Step 3: Carry out the first pickling after degreasing, wash the titanium tube after pickling, dry it after washing, annealing after drying, and straighten the titanium tube after annealing;

Step 4: Pickling the titanium tube again. After the pickling, rinse the titanium tube, dry the titanium tube after washing, and then roll the titanium tube for the second time after drying. The rolled titanium tube The finished product is degreasing, pickling after degreasing, washing the titanium tube after pickling, washing and drying, annealing after drying, and straightening the titanium tube after annealing;

Step 5: Pickling the titanium tube after straightening, repeat the above steps, and obtain the finished product after six times of rolling

channel

Introducing the Titanium Pipe Gr2 Seamless Tube for Heat Exchanger from Channel a durable and solution is reliable your heat exchange needs.

Constructed from top-notch titanium making it lightweight yet exceedingly resistant and strong to corrosion. Its construction is assures being seamless are not any points that weak the pipe causing the less vulnerable to cracks and leakages.

Boasts conductivity is very good thermal what this means is it may effortlessly transfer temperature from a medium to a different. It really a choice is heat this ideal since it guarantees efficient and temperature that effective assisting to increase the performance and lifespan of the gear.

Made for use within high-temperature and surroundings are high-pressure making sure it might withstand problems are tough companies that are several. It's also versatile which makes it ideal for used in numerous applications such as chemical processing energy generation and engineering is marine.

A task is easy install and maintain helping you save money and time in the run is quite long. Its durability and opposition to corrosion result in an also longer lifespan decreasing the necessity for frequent replacements and repairs.

Are presented in numerous sizes and specs to interest your needs are specific. It's also customizable permitting the dimensions are selected by both you and design that fit is best your requirements.

Specialized in items are providing top-notch customer support is very good. Most of us of experts will assist you to find the Titanium Pipe Seamless is ideal for temperature exchanger project. We also provide competitive rates and circulation is quick ensuring you shall obtain the item on some right time within spending plan.

The Titanium Pipe Gr2 Seamless Tube for Heat Exchanger from Channel is merely a trusted, durable, and solution is efficient your heat exchange needs. Its high-quality construction conductivity that excellent is thermal opposition to corrosion ensure it is a top option for various industries. With Channel's dedication to client and quality solution you can rely you the best services and products and help for the project on us to give.