Igama |

Isihlahla sodade futhi umgubho weTitanium |

|

Standards |

ASTM B338/ASME SB338, ASTM B337/ASME SB337, ASTM B861/ASME SB861, ASTM B862/ASME SB862, AMS4911, AMS4928 |

|

Usizo Wesigaba |

Gr1, Gr2, Gr4, Gr7, Gr9, Gr11, Gr12, noma. |

|

Ubude |

≤14000mm |

|

Ubungako mm |

Umgeni 3-508mm |

|

Ukuma kwesigaba |

Mpofu futhi Ebusuku |

|

Ukubekezelelana |

a) Umgeni waphandle: +\/– 0.01mm |

|

b) Ukuphakamisa: +\/– 0.01mm |

||

c) Ubukhulu: +\/– 0.1mm |

||

Umphetho |

Ukugqibela, ukusheya, ukulungisa, uphondo oluhlupheka |

|

Isici |

1. Ukuphakameka Okuncane Nokuthi Kuhle Ngaphandle Kwesikhombisi 2. Ukugcwaliswa Kwesibhedlela Engaphakathi 3. Ukuphakama Kubukeka Kwesihloko Lesinekhono 4. Ukuthi kusenzo kakhulu lokuhlala ngokubhebhu emaninimane 5. Ayikho umangayithi noma umthombo omkhulu 6. Amanqaku amahhovu amakhe 7. Umlume wokushona wesibhedheni esitsone |

|

Ukushicilela |

Ukushicilela, ukuhlambisana, utshwala olunyelelwa, ukutshabalalisa amacrythalline, ukusheya ngokusebenzela, NDT |

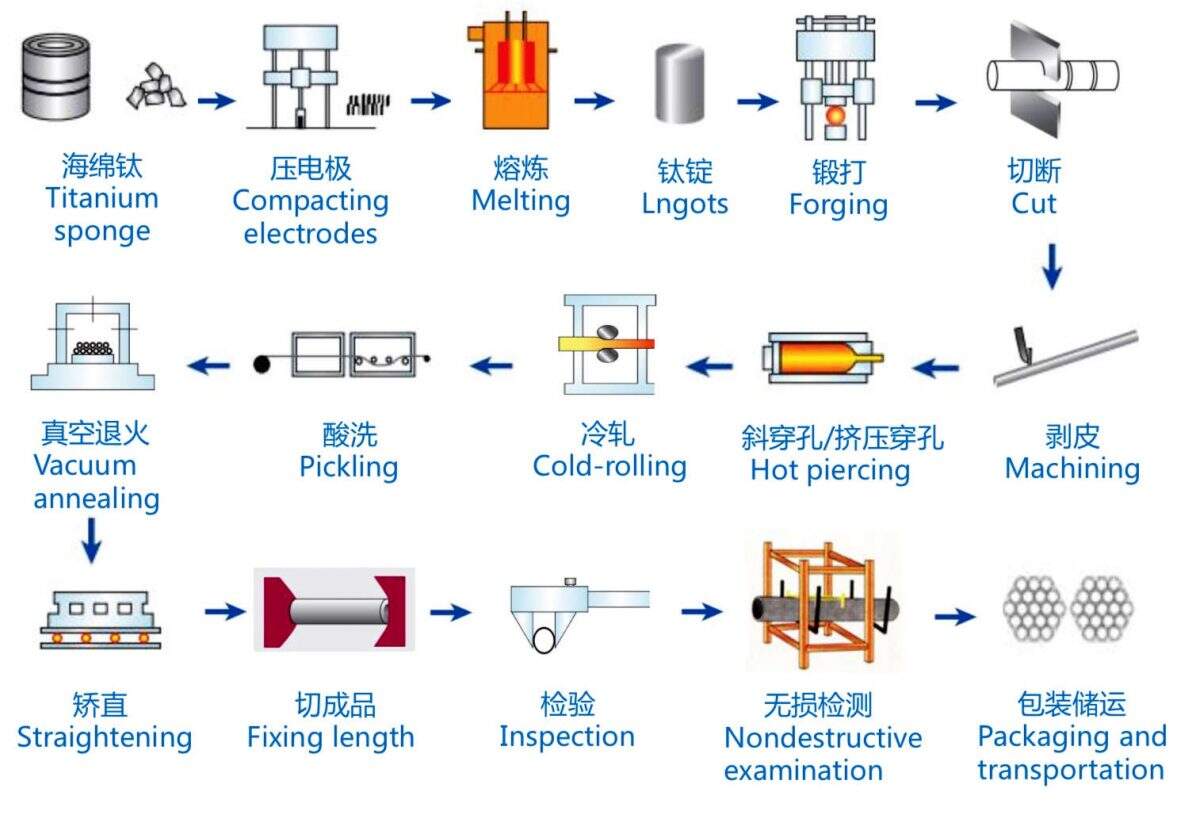

Isimo esethweni lokuhlola nokuhlanganisa amathayithi, umkhondo wahlola ngamandla okungafanelekayo:

Indlela yesibili: Ukufutha kwezingotfo zomthayithi ngokushesha, bese ukulawula isifundo sesingotfo; Indlela yesithathu: Ngemuva kokulawula kwezingotfo, uzihlabeleka eziningi lapho zihlabeleka amathayithi ngokusukela, bese uzisusa izinyosi ngemuva kokuhlabeleka ekusukeleni;

Indlela yesine: Uhlola okusukela ngemuva kokususa izinyosi, ushota amathayithi ngemuva kokuhlola, uziphatha ngemuva kokushota, uzindabeni ngemuva kokuphatha, bese uzimemeza amathayithi ngemuva kokundabeni;

Indlela eyisine: Ukugcina isibakabhulu sotitanium ngaphandle kokugcina, shisa isibakabhulu sotitanium phakathi kwezinsuku, ushisa isibakabhulu sotitanium ngaphandle kokushisa, kwaye ngemuva kokushisa ugcine isibakabhulu sotitanium ngemvume. Isibakabhulu sotitanium esegcinwe sihlola ukuthi akukho okutshelelanga, ukugcina ngaphandle kokuthi akukho okutshelelanga, shisa isibakabhulu sotitanium ngaphandle kokugcina, shisa nokushisa, uzame ukusiza ngemuva kokushisa, kwaye uzame ukubuyiselwa ngemuva kokusiza;

Indlela eyiphawuli: Ugcina isibakabhulu sotitanium ngaphandle kokubuyiselwa, hlola amaninzi okungabili ezintathu, uhambe izilungiselelo zezinsuku ezintathu eziyisixhenxe

Isichannel

Amaphupha amandla edingekileyo emagqabiwe ngokubhulukazi kwaye ezibhedhekileyo ukusuka. Amaphipha akhethiwe ngamagqude amahle okuthi titanium alloy ngenxa yalokho kulandelwa ngokusukela nezinye izigaba ezintathu, uGr2 kunye nokuGr9 - okuyingxenye yabo abo abangaphakathi babephindvule umoya wabo wesobizo nokugcina.

Kube lutho olubekelwe ngokwesiphumo esidingayo lokusebenza lokuhlola ukusasazwa kwaye kube lutho olufunekayo ukusetshenziswa kwisebe sikaqhaza. Lolu hlobo lokuthi titanium alloy luhluke kakhulu kunye nokusetshenziswa ngokushesha kakhulu ukuzama ukusetyenziswa. UGr5 grade we-titanium alloy yakwenzeka ngamandla ekubaleni kunye nokungakhoze kakhulu lokusetshenziswa kwisebe lesikhono kunye nokusetshenziswa lemaxhego. Ngakwesobukhona, uGr9 grade wetitanium alloy yakwenzeka ngokubaluleka phakathi kwamandla nokuhlola ukusasazwa okungavuko lokhu kwaye yakwenzeka ngokubaluleka futhi kakhulu kwisebe sokugcina.

Akuqala ukuthi amathambo akhona kuhlu-ndawo okuyisisekelo lokuhlola amathumbu angaba ngokuqinisekileyo - ngaphandle kokuthi kungabiko kakhulu lokulandelana nokusebenza ngenqanawe kunjalo kuzoba ukuthi isikhatsi sifanele. Imikhiqizo yethu yokuthintela e-CNC yenye yesikhathi sokugcina neziphumo zethu ezidingekayo ezincinci zingakwazi ukukhetha amathumbu aqondisiwe ngokukhulu kodwa afanele kakhulu. Izinqanawe zikhethwe ngokubhekene namandla ukuze kusetyenziswa ngasemva kwezinye izinto nokuthi umcabango wendawo ubheke.

Ngaphandle kokuba uyahlala phakathi komoto engenani okanye uzihlabelela ukwenza imigomo yomoya omkhulu okanye ushayelwa uphawu olunyelekile lungehlaweni elikhulu, uzame ukufumana uphawu olunyelekile olungaphandle kakhulu olungafanele kakhulu esebenzayo kanye nokuthi ifanele kakhulu. Ukusuka kwezilimo ezikhulu nokusebenzela nokuthi kungabiko kakhulu lokulandelana nokusebenza ngenqanawe kuhlanganisa iproduct engakhotholako nokuthi inceda ukusetshenziswa.

Ngoko ke ngaba ukhetheka kwiChannel? Kuqala, kuna isenzo esidingi lwenqanawe ehlukene emakhenkathini nezilungiselelo zethu zezi zinto ezikhoyo. Siyaziqalisa amaxesha akhona okusebenza nokugcina imibiko yethu yokuthuthukisa noma uzikhuluze izinyathelo zakho. Ngaphakathi, siphawule amagama angcono kunye nokuphucula okukhawulekileyo ukuze amandla athole amandla angcono.

Uma ungafuna umthiwane we-titanium osebenzayo, oluhlukwe nokubhala ngenqanawe yesiCNC, usetyenziswa kakhulu. Ukufika kwayo, Channel ungene lokhu olungakho nonamandla. I-Gr2, Gr5 kunye nesiGr9 yakho yamathiwane amahlukwe ayiqinisekisi lokho oluhle kwiseva esingabangeni kunye nokuzenzela kwesentengo sokusasazeka kunye nokuhlola kumncedisi kunye nezintathu.