|

Incazelo

|

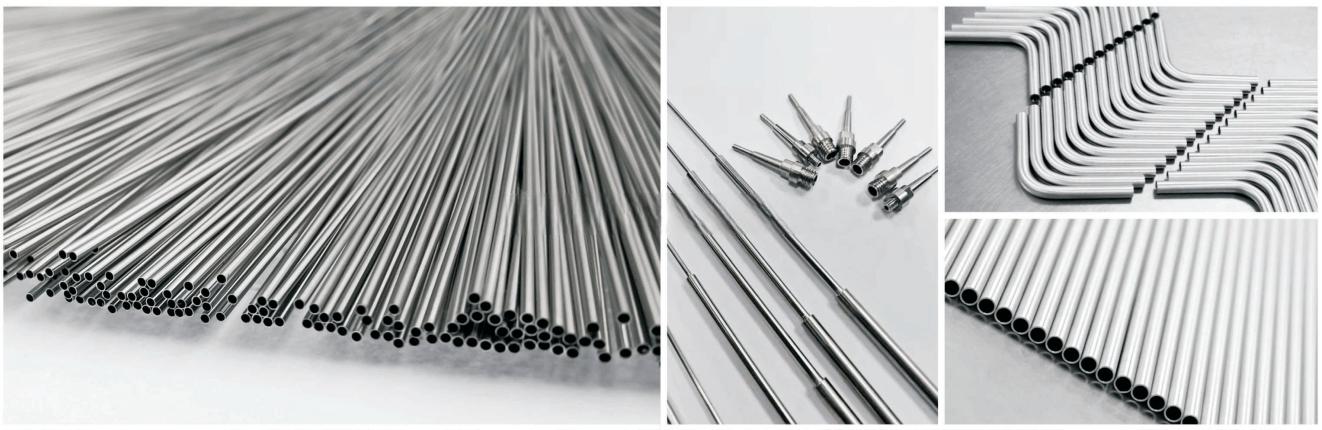

tubha lesiningquleni lenye indlela elincinci elihambisana

|

|

|

Ubungena Bucopho

|

300 tons/year

|

|

|

Isimo Sebenzi

|

cold drawn and cold rolled

|

|

|

Ukuphakama Kwesikhombisi

|

0.2mm-6mm

|

|

|

Ubuthi bokhedzelo

|

0.02mm-2mm

|

|

|

Ubude

|

1mm -3000mm

|

|

|

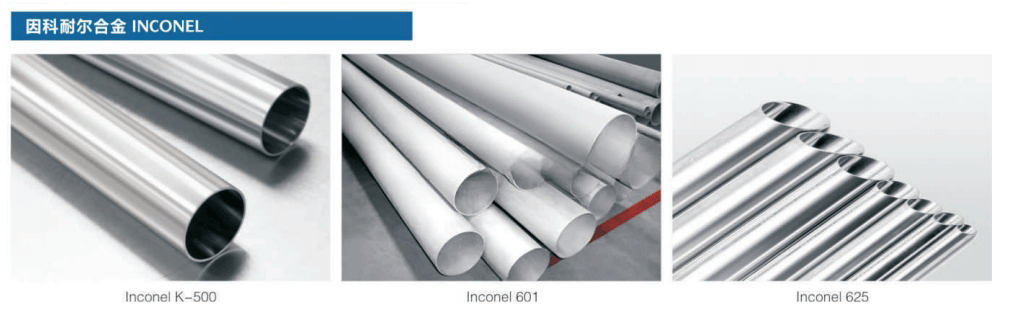

Uhlobo lweSteel

|

200 (Ni: 0.8%), 201B (Ni: 3%), 201H (Ni: 5%)

|

|

|

301 (Ni: 6%), 304, TP304, TP304L/304L, 321, TP321, 316, TP316L, 316L, 316Ti

|

||

|

317, 317L, 309S, 310S(2520), 347, Duplex 2205, Duplex 2207, Inconel 600, 625, 718 nokuhle

|

||

|

izindinganiso

|

ASTM / ASME, GB, DIN, JIS, EN, nokuhle

|

|

|

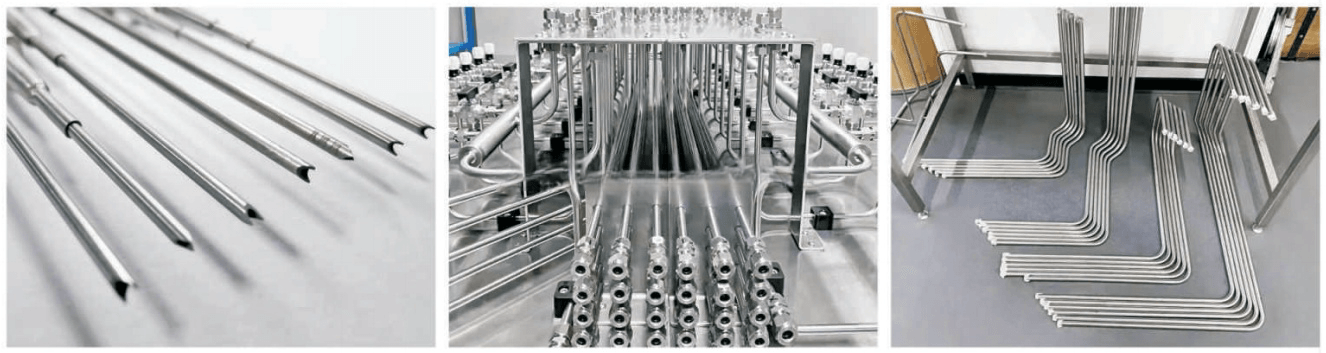

Isicelo

|

Amathuluzi amaphazamisekileyo, Ukuphucula nokubheka amanzi namakhomphulo, Isipayiphi somfihlo, nokuhle

|

|

|

Ukupakisha |

1. ngekhapu leplastiki lokuvumela amabili okwesobunxebo

|

|

|

2. isibhedele saseplastiki esikhuhlane ngaphandle kwepipe

|

||

|

3. amabhabhetho angazibekwa nge-polythene nokubhaliswe ngokukhaphazekile.

|

||

|

4. uma kudinga, bheka ngokwesikhatsi esidleleni.

|

||

|

Ukuqinisekiswa

|

ISO 9001: 2008

|

|

|

Isikhathi Sokulethwa

|

5-30 izinsuku zihangalaweni ne-Quantity

|

|

|

Ithemba Yophethela

|

T/T, Irrevocable L/C at sight

|

|

|

Iphroji yokuTrade

|

FOB, CFR, CIF

|

|

Umbala Wokuchemisela (%) |

201

|

202

|

304

|

316

|

S31803

|

S32750

|

||

|

C

|

≤0.15

|

≤0.15

|

≤0.08

|

≤0.08

|

≤0.030

|

≤0.030

|

||

|

Si

|

≤1.00

|

≤1.00

|

≤1.00

|

≤1.00

|

≤1.00

|

≤0.80

|

||

|

Mn

|

5.5-7.5

|

7.5-10.0

|

≤2.00

|

≤2.00

|

≤2.00

|

≤1.20

|

||

|

P

|

≤0.060

|

≤0.060

|

≤0.045

|

≤0.045

|

≤0.030

|

≤0.035

|

||

|

s

|

≤0.030

|

≤0.030

|

≤0.030

|

≤0.030

|

≤0.020

|

≤0.020

|

||

|

Cr

|

16-18

|

17-19

|

18-20

|

16-18

|

21-23

|

21-23

|

||

|

Ni

|

3.5-5.5

|

4.0-6.0

|

8.0-10.5

|

16.0-18.5

|

4.5-6.5

|

6.0-8.0

|

||

|

Mo

|

2.0-3.0

|

2.5-3.5

|

3.0-5.0

|

|||||

|

n

|

≤0.25

|

≤0.25

|

0.08-0.2

|

0.24-0.32

|

||||

|

Cu

|

≤0.50

|

|||||||

|

Umbuso Wokugcina |

Ukuphinda-kuphinda(MPa)

|

≥655

|

≥620

|

≥515

|

≥515

|

≥620

|

≥800

|

|

|

Ukuphinda-kuphinda ye-Yield(MPa)

|

≥260

|

≥310

|

≥205

|

≥205

|

≥450

|

≥550

|

||

|

Ukugqumela(%)

|

≥35

|

≥35

|

≥35

|

≥35

|

≥25

|

≥15

|

||

|

Hardness(HV)

|

≤230

|

≤230

|

≤200

|

≤200

|

≤303

|

≤323

|

|

Isicelo

|

Umgibhali wezimo lokushintsha

|

Amafiti ngemvume kanye nezinye zindawo, amafurniture yamabhedha, amasekshoni engakwenzekanyeni nokulandelana ngezinto ezikhona

|

|||||

|

ukusiphutha

|

Amasistimu okuhlala kwindawo yokugcina, amaphrofayile zakarhi, amatanqashi amabili, amakhonteyenti, izinkhoveli zokuchemisela nokuthi

|

||||||

|

I-Chemical/Pharmaceutical

|

Amavessels okuhlala kubukhosikethu, amapipe yokuphatha nokuthi

|

||||||

|

Oil & Gas

|

Izindawo zophandle lwezindlela, amacable wires, amaphayipayini angaphantsi nokuthi

|

||||||

|

Amameko

|

Ukuphatha kokuthi nokuthi wamameko, amapipe zamameko, amatanqashi emanzini nokuthi

|

||||||

|

Umlungu

|

Amathuluzelo asesihlathi, amathuluzelo sokususa, amascanner e-MRI nokuthi

|

||||||

|

Ukudla nokuncane

|

Amathethwenkxobo yokuphepha, ukubhokisela, uphucamayo kwezilungu nokulandelana ngezinto eziphakeme.

|

||||||

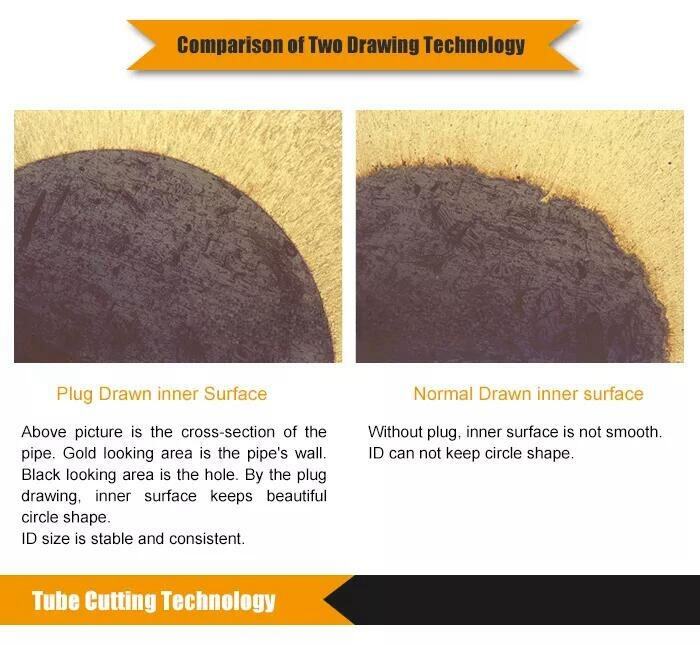

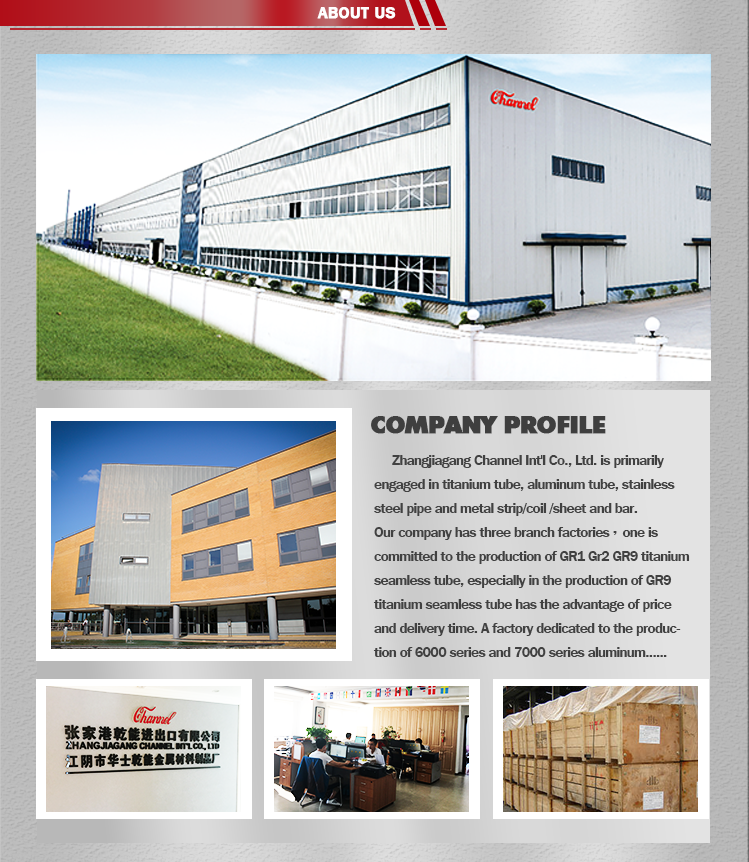

Ukukhothisha Channel's Micro 304 316 Stainless Steel Capillary Tube, umnandi wokuqinisekileyo owaziwayo ukuyihlawula izindlela eziningi zezindawo ngokushesha njengezindawo zokugcinwa, zomthwalo, kunye nezindawo zokugcina. I-capillary tube yaseChannel ifakwa yinkathelo yokuqinisekiswa yestainless steel, ukuze iChannel's capillary tube lihleliwe ukukhathalisa ukudabuka, ukukhuzwayo, kunye nokuhlola kakhulu lokulandelana ngezinto zakho.

Ukuphumelela isiqephu esihluhleni sokugcina ngaphakathi lokuvumela amaratesi akhokho, ubungako kakhulu lokulandelana nge-internal area elishushwamede. Isiphendulelanisi somsebenzi wesintshabalalo esikhoyo ukuthi lisebenzise uphawu olungaphandle komhlaba olungahambisane nokuhlola kwezinye izinto ezinethethwa ngokubuyekezo nokuhlola. Ukusuka kwesiphiwo lesigqibo lepipe elibomvu kunquma amagama angamandla, ukuze kuhamba kakhulu nokuthuthukisa kulandelana namandla. Ngokushesha, umthombo wemhlophe we-stainless steel wenkulunkulu wokuhlola okanye wokuzenzekelayo kusebenza ngokukhona kakhulu ngokuthi lisebenziswe ngokubalulekileyo kwi-applications ezidingekayo.

Benza ngamabala amadifasini nemidiamitha, ukungavalelisa abantwana bakethu iindlela ezimbili nokukhetha ukuba ziyathathelwe ngokwabo. Umthombo wencapillary wake ungacutshwayiswa, uzityenziswa, nokubuyelwa ngokusukela, okungafuneka kakhulu nokungcono ukusetshenziswa kwisekhena esincane.

Kuyahluke kakhulu lokusebenza ngokwesobizo esikhathini somedi kaloku ukuthi amaphawethi angakho akhuphe amandla. Isikhundla sesithuli sijwayelekile ngaphakathi kanti usebenziso ngokukhangelwa kwicala, amangcendu, noma izinto ezinnyamisayo ezilandelana nezinye iindlela zokususa amafomu, apho ukubaluleka kunye nekubona kuhluke kakhulu. Ukusetyenziswa kakhulu kwiindlela zemoto ezidingekileyo, uzokusiza isiphelo semafomu ngokuzenzekelayo kwiindlela ezikhoyo lokuncedzi lokuhlola phakathi komoto nokuhlola phakathi komoto. Ngakho ke, phakathi komhlaba, umphawethi wencane wekhapayili wenqanawe kunjalo kufanele ukusetshenziswa kwiindlela zakhiya nokususa igas ngaphandle kokuhlala kutsi.

Umgama lwencane lwakho luhluke kakhulu olungazange lolunikeze imigomo yeziningi ezintathu ezintathu ngaphandle kwezantsi.